The traditional art of Japanese paper making has a history that dates back well over 1,000 years. Kurotani in Kyoto is one of the oldest paper-making villages where the tradition continues in earnest, with artisans continuing the ancient practice of paper skimming, classed as an intangible cultural asset by Kyoto Prefecture.

Like all Japanese arts, the process of creating washi has a precise and meditative quality about it. From collecting and preparing the raw materials to filtering and pressing the paper, the movements of these craftspeople and the life they lead is truly a sight to behold.

Japanese filmmaker Takashi Kuroyanagi has captured these moments in a beautiful five-minute film that takes us through the process from beginning to end and the result is breathtaking in its meditative beauty. If you’re looking for a way to take five minutes to relax in a busy day, this video is the calming tonic you need.

Japanese handmade paper is known as washi; wa meaning Japanese and shi meaning paper. Kurotani washi is the subject of this film, which is set in winter, the traditional season for paper-making due to the fact that cold inhibits the growth of bacteria and pure, cold water is essential to the process.

From harvesting the field of paper mulberry to stripping the bark and pressing and drying the materials, the film transports us to a slow life where community and quiet meditation lead the way, reminding us to stop and appreciate life and the beauty of creation.

Now it’s time to make yourself a cup of green tea, put your feet up and enjoy five minutes of absolute beauty and relaxation.

If the video has piqued your interest in washi, read on for a look at the steps involved in the production process below.

▼ The kozo (paper mulberry) is indigenous to the south of Japan and is known for its strong fibres. Here the branches are steamed, dried and then stripped for their bark.

▼ The bark strips are then bundled by people of all ages to be cleaned indoors away from the cold. There’s no age discrimination at this workplace!

▼ The bark is shaved, revealing the inner fibres which will be used to make washi.

▼ The fibres are then boiled to remove any starch, fats or tannins.

▼ Then it goes into a bath of cold running water, where impurities are picked out by hand.

▼ The fibres are pounded for an hour in large vats and then a screen is dipped into the paper pulp slurry several times to form a sheet.

▼ Creating the desired thickness of the paper depends on the number of times the screen is dipped into the mix. This is an art that can only be determined by the skilled eye and hands of the craftsman.

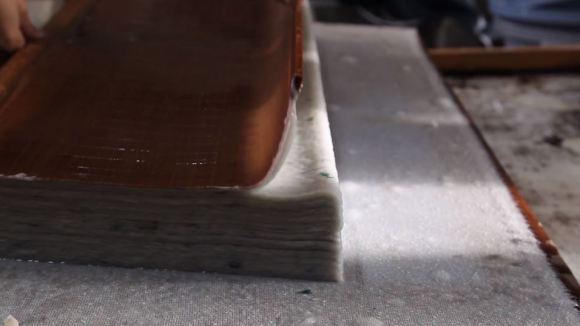

▼ The wet sheets of paper are removed from the screen and then stacked to be pressed the following day. The use of string and a binding agent ensures the papers don’t stick together.

▼ Each individual paper is then separated and pasted onto drying boards to dry naturally in the sun.

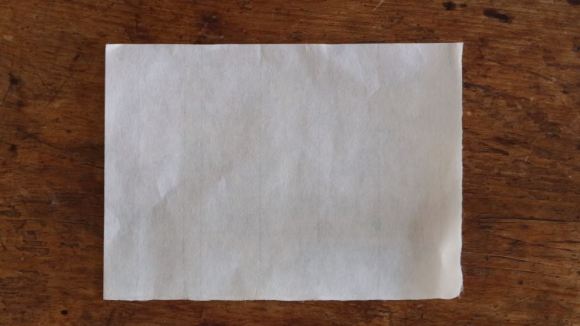

▼ Finally we get to the paper sheet we see in stores today. The even thickness and fine fibres show the high quality of their product.

Washi is so durable that it can be used for all kinds of things, including lanterns, shoji (sliding paper screens) and fusuma (sliding paper doors). Dyeing opens up even more options for its use.

It’s amazing to think that the heart of this product is actually an all-natural material. Using local water and plants in the process creates something more than just paper—it creates a special bond between artisan and community; a tradition that we hope to see continue for centuries to come.

Source and screenshots: Kuroyanagi Takashi Vimeo

Samurai parkas for men feature traditional washi Japanese paper details

Samurai parkas for men feature traditional washi Japanese paper details Traditional Japanese washi paper features Totoro and friends in 20 beautiful seasonal scenes

Traditional Japanese washi paper features Totoro and friends in 20 beautiful seasonal scenes Mino City’s traditional paper lanterns illuminate its historic streets this fall

Mino City’s traditional paper lanterns illuminate its historic streets this fall Keanu Reeves teams up with Suntory for new series exploring Japanese whisky and monozukuri【Video】

Keanu Reeves teams up with Suntory for new series exploring Japanese whisky and monozukuri【Video】 Viral Japanese cheesecake from Osaka has a lesser known rival called Aunt Wanda

Viral Japanese cheesecake from Osaka has a lesser known rival called Aunt Wanda Ramen for 99 yen?!? Best value-for-money noodles found at unlikely chain in Japan

Ramen for 99 yen?!? Best value-for-money noodles found at unlikely chain in Japan Lawson adds doughnuts to its convenience store sweets range, but are they good enough to go viral?

Lawson adds doughnuts to its convenience store sweets range, but are they good enough to go viral? Japan Extreme Budget Travel! A trip from Tokyo to Izumo for just 30,000 yen [Part 2]

Japan Extreme Budget Travel! A trip from Tokyo to Izumo for just 30,000 yen [Part 2] Japan’s craziest burger chain takes menchi katsu to new extreme levels

Japan’s craziest burger chain takes menchi katsu to new extreme levels Kyoto’s “ikezu” culture of backhanded compliments explained in hilarious souvenir sticker series

Kyoto’s “ikezu” culture of backhanded compliments explained in hilarious souvenir sticker series The best Hobonichi diaries, covers and stationery for 2026

The best Hobonichi diaries, covers and stationery for 2026 Ginza hotel serves up one of the best breakfasts in Tokyo

Ginza hotel serves up one of the best breakfasts in Tokyo Japanese farming simulator rewards players with actual crops delivered to their door

Japanese farming simulator rewards players with actual crops delivered to their door Everyday Japanese names that make English speakers chuckle

Everyday Japanese names that make English speakers chuckle Starbucks Japan releases first-ever Hinamatsuri Girls’ Day Frappuccino

Starbucks Japan releases first-ever Hinamatsuri Girls’ Day Frappuccino Japanese restaurant chain serves Dragon Ball donuts and Senzu Beans this spring

Japanese restaurant chain serves Dragon Ball donuts and Senzu Beans this spring Highest Starbucks in Japan set to open this spring in the Tokyo sky

Highest Starbucks in Japan set to open this spring in the Tokyo sky Tokyo Skytree turns pink for the cherry blossom season

Tokyo Skytree turns pink for the cherry blossom season Japan Extreme Budget Travel! A trip from Tokyo to Izumo for just 30,000 yen [Part 1]

Japan Extreme Budget Travel! A trip from Tokyo to Izumo for just 30,000 yen [Part 1] Yakuzen ramen restaurant in Tokyo is very different to a yakuza ramen restaurant

Yakuzen ramen restaurant in Tokyo is very different to a yakuza ramen restaurant Japan has only one airport named after a samurai, so let’s check out Kochi Ryoma【Photos】

Japan has only one airport named after a samurai, so let’s check out Kochi Ryoma【Photos】 Japanese drugstore sells onigiri at pre-stupid era prices, but how do they compare to 7-Eleven?

Japanese drugstore sells onigiri at pre-stupid era prices, but how do they compare to 7-Eleven? Adorable Totoro acorn key holders come with a special guest hidden inside[Photos]

Adorable Totoro acorn key holders come with a special guest hidden inside[Photos] Japan’s newest Shinkansen has no seats…or passengers [Video]

Japan’s newest Shinkansen has no seats…or passengers [Video] Starbucks Japan releases new sakura goods and drinkware for cherry blossom season 2026

Starbucks Japan releases new sakura goods and drinkware for cherry blossom season 2026 Foreigners accounting for over 80 percent of off-course skiers needing rescue in Japan’s Hokkaido

Foreigners accounting for over 80 percent of off-course skiers needing rescue in Japan’s Hokkaido Super-salty pizza sends six kids to the hospital in Japan, linguistics blamed

Super-salty pizza sends six kids to the hospital in Japan, linguistics blamed Starbucks Japan unveils new sakura Frappuccino for cherry blossom season 2026

Starbucks Japan unveils new sakura Frappuccino for cherry blossom season 2026 Foreign tourists in Japan will get free Shinkansen tickets to promote regional tourism

Foreign tourists in Japan will get free Shinkansen tickets to promote regional tourism The 10 most annoying things foreign tourists do on Japanese trains, according to locals

The 10 most annoying things foreign tourists do on Japanese trains, according to locals Take a trip to Japan’s Dododo Land, the most irritating place on Earth

Take a trip to Japan’s Dododo Land, the most irritating place on Earth Naruto and Converse team up for new line of shinobi sneakers[Photos]

Naruto and Converse team up for new line of shinobi sneakers[Photos] Is China’s don’t-go-to-Japan warning affecting the lines at a popular Tokyo gyukatsu restaurant?

Is China’s don’t-go-to-Japan warning affecting the lines at a popular Tokyo gyukatsu restaurant? Survey asks foreign tourists what bothered them in Japan, more than half gave same answer

Survey asks foreign tourists what bothered them in Japan, more than half gave same answer Japan’s human washing machines will go on sale to general public, demos to be held in Tokyo

Japan’s human washing machines will go on sale to general public, demos to be held in Tokyo Starbucks Japan releases new drinkware and goods for Valentine’s Day

Starbucks Japan releases new drinkware and goods for Valentine’s Day We deeply regret going into this tunnel on our walk in the mountains of Japan

We deeply regret going into this tunnel on our walk in the mountains of Japan Studio Ghibli releases Kodama forest spirits from Princess Mononoke to light up your home

Studio Ghibli releases Kodama forest spirits from Princess Mononoke to light up your home Major Japanese hotel chain says reservations via overseas booking sites may not be valid

Major Japanese hotel chain says reservations via overseas booking sites may not be valid Put sesame oil in your coffee? Japanese maker says it’s the best way to start your day【Taste test】

Put sesame oil in your coffee? Japanese maker says it’s the best way to start your day【Taste test】 No more using real katana for tourism activities, Japan’s National Police Agency says

No more using real katana for tourism activities, Japan’s National Police Agency says